- Paper Packaging

- Cake & Bakery Packaging

- Disposable Cups

- Disposable Lunch Packaging

- Disposable Cutlery

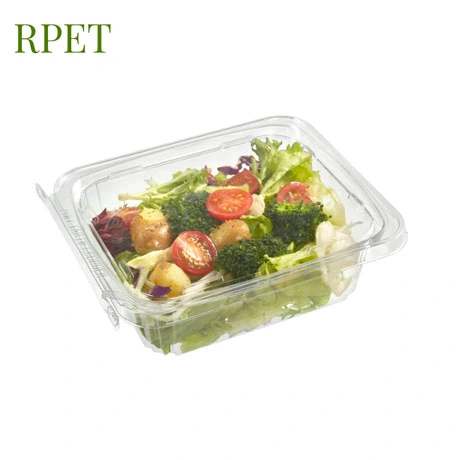

- Disposable Salad Container

- Disposable Fruit & Vegetable Container

- Disposable Trays Packaging

- Tamper Evident Container

- PLA Food Packaging

- Sushi Tray

- Pastry Packaging With Seal Film

- RPET Recycled Packaging

- Stretch Film Sheet

- Prepared Dishes Packaging With Seal Film

- Wholesale Clear Square Packaging Plastic 16oz Snacks Box Tamper Evident Nut Box

- 8 16 24 32 46 64 128 Oz Tamper Evident Container Packaging Box for Nuts Food

- Disposable Hinged Lid Food Takeaway Clear Rip off Seal PET TAMPER-EVIDENT Box

- Wholesale Round Seal Food Grade Nut and Fruit Container 8oz Tamper Evident Box

- Factory 16 Oz Pet Transparent Tamper Evident Seal Disposable Plastic Hinged Containers

- Wholesale Square Plastic Hinged Salad Food Nut Vegetable Container Tamper Evident Container

- 240ml Custom Biodegradable PLA Disposable Food Restaurant Paper Takeaway Container

- 360ml Eco Friendly PLA Customized Printed Black Packaging Carton For De;li Food

- 500ml Takeaway Biodegradable PLA plastic Food Box Salad Box Bowl

- 600ml Custom Printed Biodegradable Disposable PLA Takeaway Box With Transparent PLA Lid

- 700ml Biodegradable Kraft Paper Lunch Box with PLA Window PLA Container

- Transparent Disposable Plastic Sushi Packing Container Tray

- Disposal Take Out Plate 12 Inch Food Tray Disposable Large Black Color Round Container Plastic Sushi Box For Takeaway

- Eco Friendly Food Grade Disposable Plastic Sushi Container Food Tray With Lid

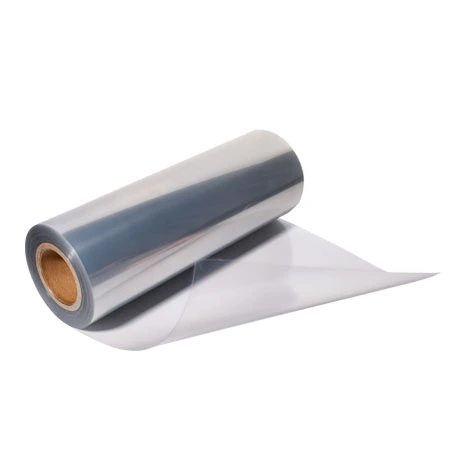

- PS/PP/PET container Sealing Film Heat Seal Lidding Film Fast Food Tray Packaging Film

- High Barrier Pa/Evoh/Pe Cheese Packaging Peelable Top Film

- Cheese Packaging Box Thermoformer For MAP In Rigid Film

- Cheese Dairy Snacks Packaging Solutions Peel Reseal Lidding Films

- High Barrier Films For Food Packaging Trays

- Flexible Food Packaging Manufactory Plastic Cobtainer With Top Lidding Film

What are you looking for?

EN

EN

CN

CN