Wholesale Food Packaging Boxes: What to Know Before Ordering

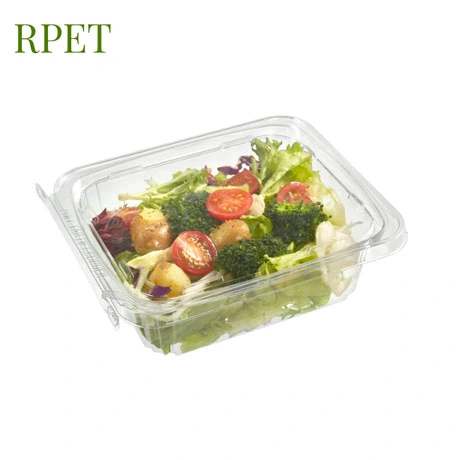

In the food industry today, food packaging is not simply putting a container around a product in order to keep its form. It also plays a part in marketing and meeting the necessary regulations. For a restaurant owner, a food manufacturer, or even a grocery brand, understanding these factors when ordering wholesale food packaging boxes remains critical to the success of your business. This thorough guide will step you through the most important factors that guarantee function, value, and savings when choosing wholesale packaging for food products Your choice of materials for packaging defines its effectiveness. Packaging must be food-safe, nontoxic, and all regulations must be satisfied. If customers are to trust that their food is safe, then poor quality materials cannot be used. Otherwise, it is important to note that using poor-quality materials can lead to customer dissatisfaction. What are the factors that need to be considered in choosing a food packaging material? In this case, you need to determine if the material is durable, leak-proof, biodegradable, heat or moisture-resistant, and has food-grade certification. The following are examples of materials that are safe for use with food products: Kraft/Cardboard Paper: Customizable and Eco-Friendly. Plastic (BPA-free): Provides clear visibility and is leak-proof. Foil-lined or wax-coated paper: Resists grease and retains heat. Corrugated fiberboard: Provides insulation and is strong. Always ensure that the packaging supplier meets local food safety regulations, FDA compliance and request certificates when necessary. Different food items demand unique handling techniques. For example, hot, greasy foods require an oil-proof package, while frozen products require moisture-proof insulation. What are the basic requirements of food packaging? It has to cover the food, avoid contamination, keep it fresh, and allow transportation without damage. For example: Bakery goods may need promotional window boxes. Soups and other liquids should be contained in non-leakable containers. Fresh vegetables might need a permeable, non-woven fabric that allows air in and not out. Other micro-perforated films can also let gasses and vapors exit but not enter. Choosing the right type of packaging for your product will keep it safe, extend its shelf life, and protect its quality even during transportation. The food product packaging should serve as a marketing tool. Custom-printed boxes offer a unique branding opportunity and memorable unboxing experience. What are the 3 factors that make a good packaging design? It combines the package appearance, its functionality, and how the brand marketers use it for advertisement. All these components work together to create a design and achieve customer retention or loyalty. Important features include customization such as: Placement and colors of the logo. Different measurements and dimensions. Window cut-outs, handles, and various forms of embossing. Eco-friendly inks and coatings. A well-designed branded package builds recognition and encourages repeat purchases. That is why at LESUI, we offer high-quality custom food packaging boxes, especially to elevate your branding and customer experience. An order made in bulk requires a clear understanding of the minimum order quantity (MOQ). Some packaging suppliers start with a high minimum initial order, which may not suit smaller businesses. What are the 3 main P's of packaging? Protection of the product, advertising, and utility. All these factors are important in a bulk order for food packaging, which needs to be stored, transported, and displayed efficiently. Ask suppliers these: Minimum order quantity and discount levels for bulk purchases. How flexible is it to re-order in smaller quantities? What are the customization options for various quantities ordered? Bulk purchasing can greatly reduce costs per unit but is limited by the available space for storage and the rate at which you sell the product. The food business operates on a timeliness motto. Any delay in packaging can delay launches or disrupt your supply chain. What are the criteria for selecting packaging? As with all vendor evaluations, turnaround time, material grade, strength, brand trust, and degree of tailoring must be analyzed. Before placing an order, check that the vendor meets the following requirements: Average turnaround durations. Availability of expedited order options. Provision of shipping and relocation logistics. Trustworthiness and clarity of the vendor. Communication channels and availability of the vendor The Packaging LESUI provides is not only reliable but also helps clients serve the market without being too flexible on quality. The cost and quality of a single box should not be your range of focus, your packaging needs to have a multi-faceted approach to value. What are the 5 requirements of packaging? Safeguarding, ease of use, sustaining the product, economy, and adherence to set policies and rules. Consider: Design and material expenses. Postage and transport costs. Finalization and print expenditures. Wastage and return materials. Always ask for detailed reports from numerous vendors to look for the best price. Remember that spending on more appealing packaging reduces spoilage and enhances branding, thus increasing long-term value. Packaging, especially in the food business, affects customer supply chains, which creates the need to offer timely deliveries. Food customers are increasingly valuing eco-friendly and environmentally responsible options. In contrast, sustainable packaging is an advantage that differentiates businesses from their competitors. What are the 4 C's of packaging? Like any other type of packaging, it contains, communicates, offers convenience, and conserves. These principles are crucial for designs that care about the environment. Environmentally friendly options include: Kraft paper and cardboard that can be recycled. Biodegradable or compostable packaging. Soy or water-based inks. Strong takeaway boxes and other similar designs that can be reused. Businesses that focus on these principles stand better chances of gaining new customers and meeting future laws and regulations. Packaging needs to adhere to local food safety, labeling, and environmental laws. This includes: FDA approval (for US clients). EU rules for contact materials. Allergen labeling, expiration dates, country of origin labeling, and more. What are the important 4 considerations in packaging design? Safety and functionality, compliance with rules, and branding are equally important when creating and choosing food packaging. Ask your supplier if they hold ISO 22000, FSC (Forest Stewardship Council), or other relevant documents. The rest of your supply chain depends on the quality of your packaging supplier. Choose a supplier with a strong reputation, clear policies, and quick-response customer support. What are the 7 basic steps to packaging design? The steps include researching, analyzing the product, defining the packaging brief, concept design, prototyping, testing, and final production. It is important to partner with a knowledgeable supplier as they help in executing these steps accurately. Questions to ask: Do they offer design consultation services? Can you obtain samples before the bulk production starts? Do they provide payment plans or payment guarantees? Knowing the important points when purchasing wholesale food packaging boxes will save you time, money and even help you avoid the hustle in the future. Material choice, branding, costant controls, and compliance are all part of the process of packaging, but they greatly influence the product’s perception and protection.

Key Factors When Ordering Wholesale Food Packaging Boxes

1. Choose Food-Safe, High-Quality Materials

Food-safe materials include:

2. Evaluate the Type of Your Food Products

3. Add Branding and Customization

4. Order Volume and Minimum Order Quantities

5. Schedules of Production Activities and Lead Times

6. Budget and Cost Evaluation

7. Environmentally Friendly and Sustainable Practices

8. Regulatory compliance and certifications

9. Supplier reliability and customer support

Conclusion

EN

EN

CN

CN